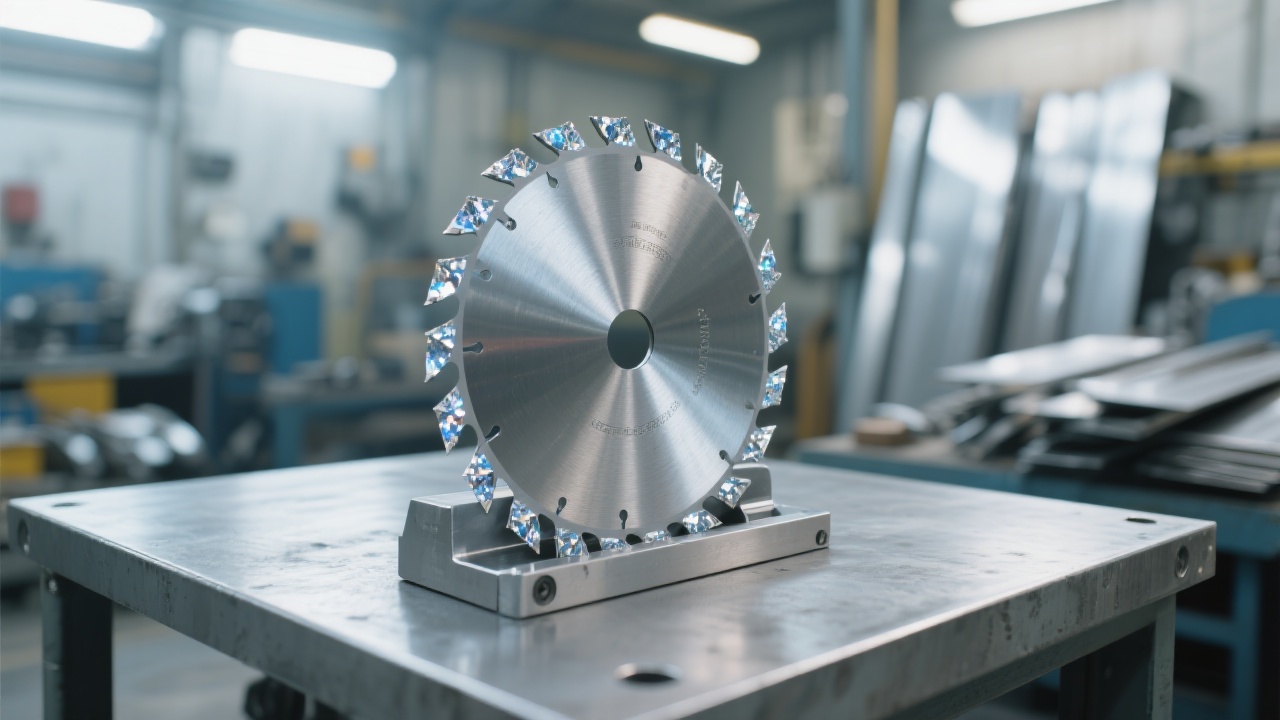

In the demanding world of industrial cutting, traditional blades often face critical challenges when applied to hard materials such as gray cast iron, stainless steel, cemented carbides, and stone. Their short lifespan, low efficiency, and environmental drawbacks pose significant operational bottlenecks. This article presents a deep dive into real-world applications of brazed diamond blades, showcasing how their advanced design elevates cutting performance, durability, and sustainability—transforming them into more than just tools, but essential productivity enhancers.

Conventional resin-bonded or abrasive blades typically exhibit rapid wear when cutting highly abrasive or dense materials, causing frequent replacements and increased downtime. Additionally, inefficient cutting processes generate excessive dust and pose safety risks. These inefficiencies translate directly into inflated labor costs and compromised workplace safety compliance.

A leading mechanical machining plant integrated brazed diamond blades to slice ductile iron components. The result was a remarkable increase in single blade life—tripling operational hours versus resin blades—while reducing manual intervention by 25%. Smooth cuts with minimal burrs translated into less finishing work and faster throughput.

At a stone fabrication facility, the adoption of brazed diamond blades for ceramic tile cutting yielded superior surface finishes, completely avoiding chipping and edge breaks common with alternatives. More importantly, airborne particulate emissions decreased by approximately 60%, allowing the plant to meet stringent environmental regulations effortlessly.

The superior results stem from an innovative combination of a manganese steel substrate and precision-aligned industrial-grade diamond particles. The manganese steel base confers exceptional toughness and resistance to deformation, while the brazing process ensures the diamond abrasives remain locked in a stable, sharp array, minimizing abrasive loss during operation. This synergy yields blades that stay sharp far longer and maintain steady cutting efficiency.

| Performance Metric | Traditional Resin Blade | Brazed Diamond Blade |

|---|---|---|

| Average Lifespan (cuts) | 100 | 300+ |

| Dust Emission Reduction | Baseline | 60% Reduction |

| Labor Cost Impact | Standard | 25% Cost Savings |

Beyond lifespan extension, brazed diamond blades deliver operational efficiencies through reduced energy consumption — attributed to smoother cutting and less friction — and lower maintenance downtime. The improved safety profile reduces risks of operator exposure to hazardous dust and blade failures, translating into fewer workplace incidents and insurance claims.

Equipment supervisors and frontline operators consistently recognize brazed diamond blades as a game-changer. One production manager commented, “Not only did we cut our tool replacement frequency drastically, but the consistency in cut quality also improved product uniformity.” Such feedback corroborates quantitative data and validates widespread market acceptance.

The convergence of durability, precision, and environmental responsibility encapsulates why an increasing number of enterprises embrace brazed diamond blades as their preferred cutting solution. They are not merely tools but productivity upgrade solutions, turning each blade into a value-generating asset on the production floor.