In the industrial cutting realm, businesses often grapple with a series of challenges. High tool wear rates lead to frequent replacements, driving up costs. Inefficient cutting processes result in low productivity, hampering overall operational efficiency. For instance, traditional saw blades may need replacement every 50 hours of use, and their cutting speed can slow down significantly after 30 hours, causing delays in production schedules and increased labor costs.

The 400H brazed diamond saw blade stands out with its unique combination of brazing technology and high - quality diamond particles. The brazing process ensures a firm bond between the diamond particles and the blade substrate. This not only enhances the blade's overall strength but also allows the diamond particles to maintain their position during high - speed cutting. As a result, the blade's wear resistance is improved by up to 30% compared to conventional saw blades. The specially selected diamond particles have sharp edges and excellent hardness, enabling them to cut through various materials with ease. This combination of technologies gives the 400H saw blade a cutting efficiency that is 25% higher than that of ordinary saw blades.

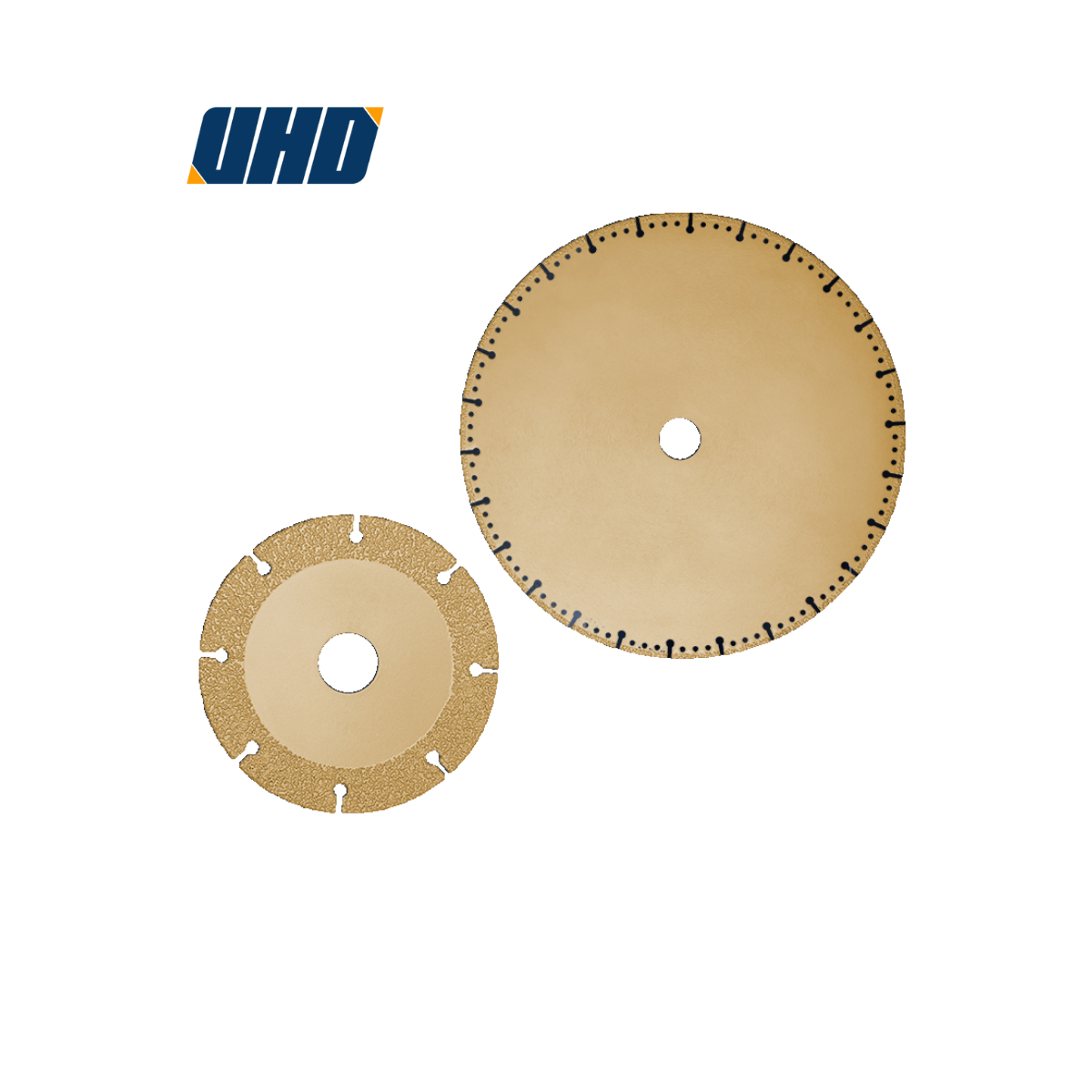

An effective heat dissipation design is another highlight of the 400H saw blade. During the cutting process, a large amount of heat is generated, which can affect the performance and lifespan of the saw blade. The 400H saw blade features a well - designed heat dissipation structure, as shown in the following schematic diagram. This design helps to quickly transfer heat away from the cutting area, reducing the temperature of the blade and preventing thermal damage. As a result, the blade's lifespan can be extended by an additional 20%.

.png)

The 400H brazed diamond saw blade has found wide applications in various industries, such as construction and stone processing. In the construction industry, it is used for cutting concrete, bricks, and asphalt. For example, in a large - scale building project, using the 400H saw blade reduced the cutting time of concrete columns by 40%, allowing the project to be completed ahead of schedule. In the stone processing industry, it can cut granite, marble, and other hard stones with high precision. A stone processing factory reported that after switching to the 400H saw blade, the waste rate of stone cutting decreased from 8% to 3%, saving a significant amount of raw materials.

Recognizing that different industries and customers have unique requirements, the manufacturer of the 400H saw blade offers comprehensive customization services. Whether it is adjusting the size of the saw blade, changing the concentration of diamond particles, or modifying the shape of the blade teeth, the manufacturer can meet the specific needs of customers. This flexibility allows customers to get the most suitable saw blade for their operations, maximizing cutting efficiency and reducing costs.

| Indicators | Before Using 400H Saw Blade | After Using 400H Saw Blade |

|---|---|---|

| Tool Replacement Frequency | Every 50 hours | Every 80 hours |

| Cutting Time per Unit | 10 minutes | 7 minutes |

| Annual Tool Cost | $10,000 | $6,000 |

| Annual Labor Cost for Cutting | $15,000 | $10,000 |

As shown in the table above, using the 400H saw blade can significantly reduce both tool and labor costs. The longer lifespan of the saw blade means fewer replacements, and the higher cutting efficiency shortens the cutting time, leading to a more productive workforce.

Many users have shared their positive experiences with the 400H brazed diamond saw blade. A factory manager said, "The 400H saw blade has truly changed our production process. Our cutting efficiency has increased, and our costs have decreased. It's a great investment." Another customer from the construction industry commented, "We used to struggle with slow - cutting and short - lived saw blades. Since we switched to the 400H saw blade, our projects have become much smoother."

Do you find that your cutting efficiency is limited by tool wear? If so, the 400H brazed diamond saw blade is the solution you've been looking for. It offers a reliable way to upgrade your industrial cutting equipment, reduce costs, and boost productivity. With its advanced technology, wide - range of applications, and customizable services, it is a game - changer in the industrial cutting field.