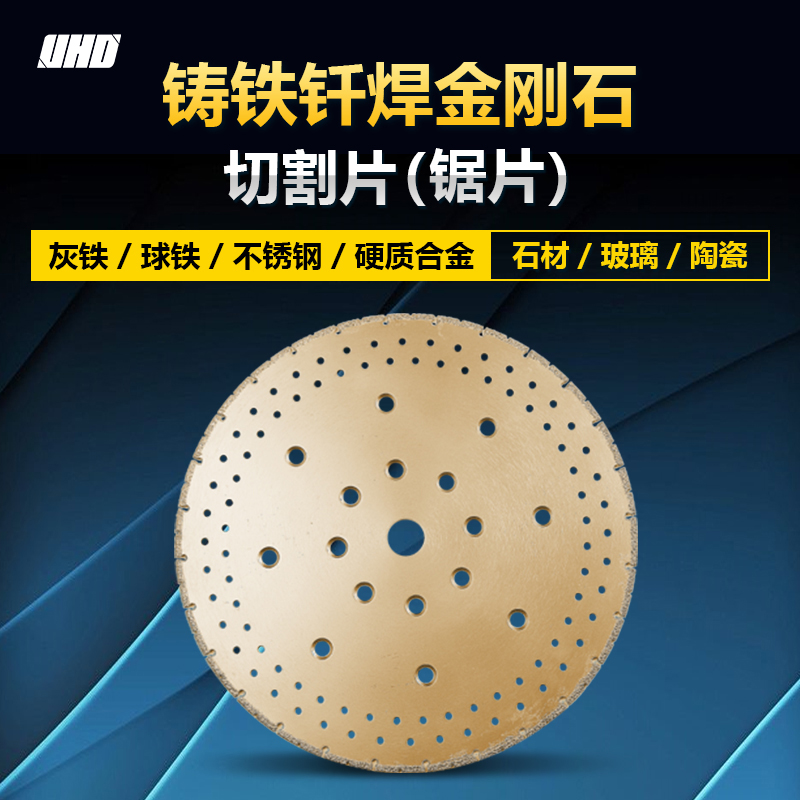

In the highly competitive industrial manufacturing landscape, companies are constantly on the lookout for tools that can enhance efficiency while reducing costs. One such revolutionary tool that has been making waves is the brazed diamond saw blade 400. This article delves into real - world customer experiences, highlighting how this saw blade has transformed operations and brought about significant savings.

Many companies initially relied on traditional resin saw blades. However, these blades had limitations in terms of lifespan and cutting efficiency. A customer, a medium - sized manufacturing firm, was facing challenges in cutting various materials like grey cast iron, stainless steel, and ceramics. The frequent blade replacements were not only costly but also caused production delays.

After switching to the brazed diamond saw blade 400, the company witnessed a remarkable change. One of the front - line workers, John, shared his experience: "With the old resin saw blades, we had to change them every 20 - 30 cuts. But the brazed diamond saw blade 400 can handle over 200 cuts before any significant wear. It's a game - changer for us."

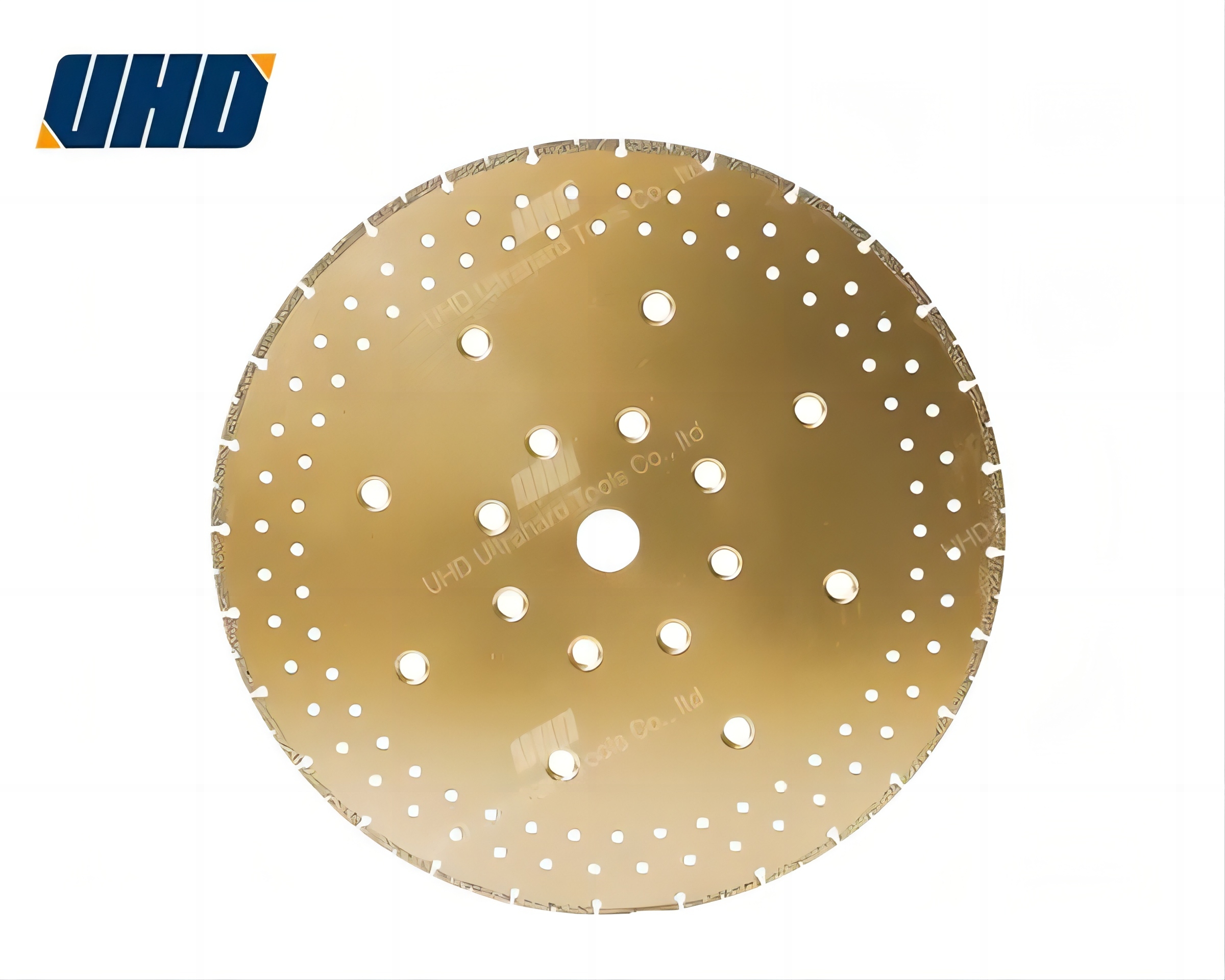

The long lifespan of the brazed diamond saw blade 400 can be attributed to its superior materials. It uses high - grade diamond particles and a high - manganese steel substrate. The diamond particles provide excellent cutting ability, while the steel substrate ensures stability and durability.

Let's look at the cost analysis. Before the switch, the company was spending approximately $500 per month on resin saw blades. After adopting the brazed diamond saw blade 400, the monthly blade cost dropped to $150. This represents a cost savings of 70%. Additionally, the reduced downtime for blade replacement led to a 30% increase in production efficiency.

| Saw Blade Type | Monthly Cost ($) | Production Efficiency Increase |

|---|---|---|

| Resin Saw Blade | 500 | N/A |

| Brazed Diamond Saw Blade 400 | 150 | 30% |

The brazed diamond saw blade 400 is not limited to a single material. It has proven its worth in multiple industries. In the construction industry, it can cut through concrete and bricks with ease. In the glass industry, it provides precise cuts without chipping. In the metalworking industry, it can handle tough materials like stainless steel and titanium.

Beyond cost savings and efficiency, the brazed diamond saw blade 400 offers environmental and safety benefits. Traditional saw blades generate a large amount of dust during cutting, which is harmful to workers' health and the environment. The brazed diamond saw blade 400 produces 60% less dust, creating a cleaner and safer working environment.

The company's safety manager, Tom, commented: "The reduced dust not only protects our workers but also means less cleaning time. And the blade's stability reduces the risk of accidents. It's a win - win for us."

To further illustrate the advantages, let's look at some more data. The replacement frequency of the resin saw blades was once every 2 days, while the brazed diamond saw blade 400 only needs to be replaced every 15 days. This represents an 86% decrease in replacement frequency. The unit labor cost also dropped by 25% due to increased production efficiency.

In conclusion, the brazed diamond saw blade 400 offers a comprehensive solution for industrial cutting needs. It provides a cost - effective, efficient, and safe alternative to traditional saw blades. With its wide applicability, environmental benefits, and long lifespan, it is truly a tool worth investing in. If you're tired of high costs, low efficiency, and safety concerns, make the switch to the brazed diamond saw blade 400 and experience the 省心, 省钱, 省力 (peace of mind, cost savings, and labor - saving) benefits for yourself. Click here to learn more and place your order today!