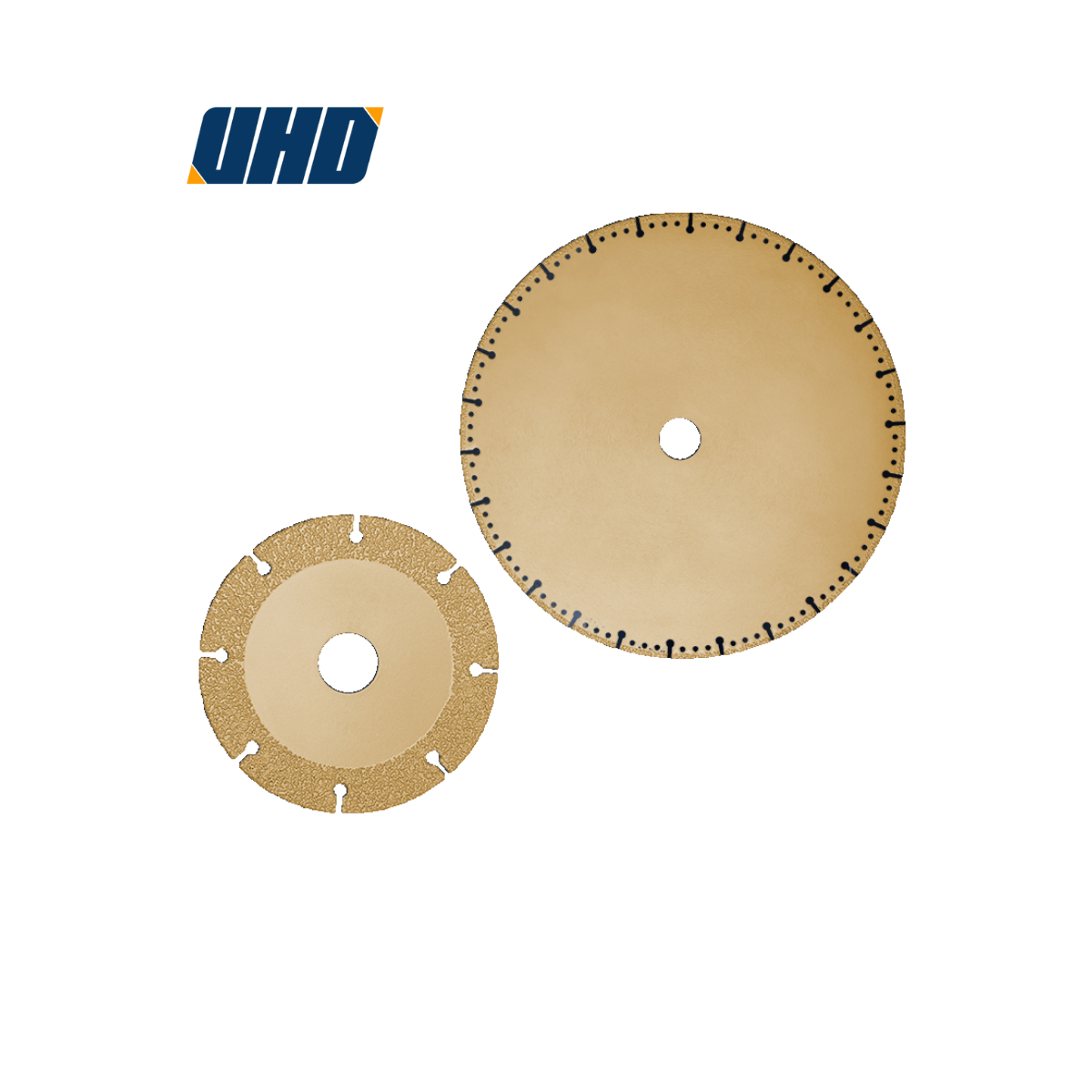

In today’s high-demand industrial sectors, precision and efficiency in cutting hard materials define competitive advantage. The 400H Brazed Diamond Saw Blade emerges as a premium solution engineered to address these rigorous expectations. Designed with superior diamond grits and robust brazing technology, the 400H blade offers unmatched durability and cutting performance across various challenging applications.

At the heart of the 400H saw blade lies a meticulously crafted combination of high-grade industrial diamonds embedded through advanced brazing techniques. This process ensures a permanent bond between diamond particles and the steel substrate, resulting in outstanding abrasion resistance and a prolonged service life—up to 40% longer than conventional sintered blades.

Beyond material quality, the blade's architecture features an optimized segment geometry and an innovative heat dissipation system. These design elements reduce operational vibration by approximately 25%, which not only enhances cut precision but also significantly improves operator safety and comfort during extended use.

| Feature | Benefit | Performance Metric |

|---|---|---|

| High-strength brazing | Enhanced diamond retention | +40% lifespan compared to sintered blades |

| Optimized segment design | Improved cutting precision | Up to 15% reduced kerf width |

| Unique heat dissipation system | Reduced thermal degradation | Operational temperature lowered by 20% |

| Vibration dampening feature | Enhanced operator safety and comfort | 25% vibration reduction |

The 400H blade's adaptability shines in an array of industries requiring precision hard-material cutting. Its formidable edge effectively handles:

This broad applicability is supported by its customizable design options. Clients can tailor blade size, diamond concentration, and segment shape to match specific cutting profiles, turning the 400H into a highly specialized tool for complex operational demands.

“By switching to the 400H brazed diamond blade, our manufacturing downtime was cut by 30%, and overall cutting precision improved noticeably, enabling us to reduce material waste significantly,” says a leading stone fabrication company from Italy.

The phrase “durability is the key” resonates strongly with 400H users. The blade’s extended lifespan and precision reduce the frequency of blade replacements and reworks, directly lowering operational costs. On average, enterprises report a 20-35% reduction in overall cutting expenses after transitioning to the 400H solution.

Moreover, the improved cutting speed — up to 15% faster than conventional alternatives — boosts throughput without compromising quality, unlocking new levels of productivity for industrial operations.

.png)

Understanding the uniqueness of each industrial application, the 400H blade supports full customization—from diamond grit size to segment configuration and bonding techniques. This flexibility ensures the blade precisely matches the operational requirements and environmental conditions faced by different businesses.

Such a tailored approach not only optimizes blade lifespan and cutting efficiency but also contributes to safer work environments by minimizing unexpected failures and enhancing machine compatibility.