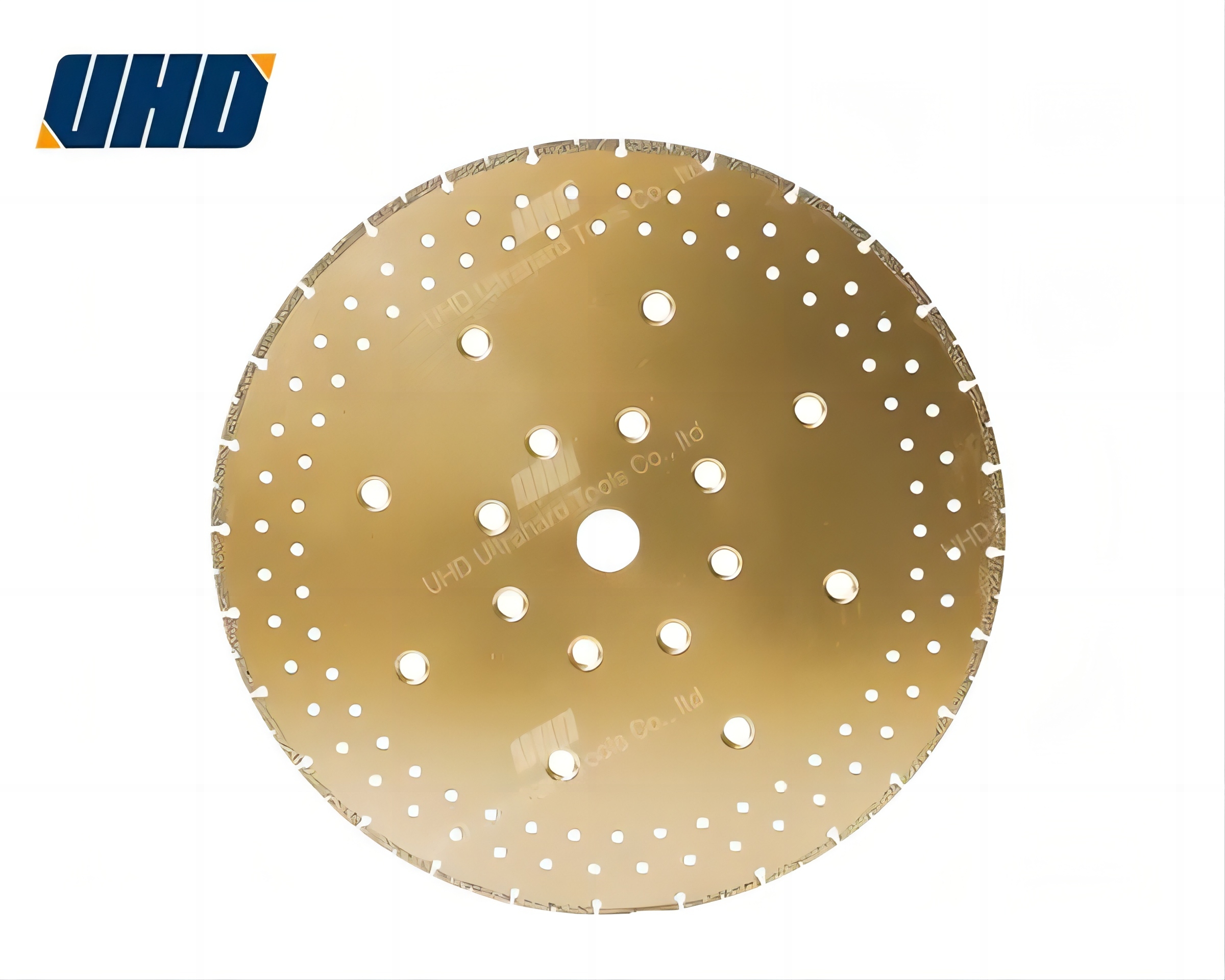

For professionals demanding precision, durability, and consistent performance in stone cutting applications—whether working with granite, marble, or engineered quartz—the 400H brazed diamond saw blade from Henan Yode Superhard Tools Co., Ltd. stands out as a benchmark solution. Engineered for high-intensity operations, this blade combines advanced material science, optimized structural design, and real-world testing to deliver measurable results that matter.

The 400H blade features premium-grade synthetic diamonds (typically 40–60 carat size) bonded via a copper-based brazing alloy at 850°C–950°C. This process ensures minimal grain loss during operation and up to 30% longer life compared to standard sintered blades under similar conditions (based on lab tests conducted by Yode R&D team). The blade’s kerf width is precisely maintained at 1.2 mm ± 0.05 mm—a critical factor for minimizing material waste while maintaining clean cuts across hard substrates like concrete, ceramic tiles, and natural stone.

| Application Material | Cutting Speed (m/min) | Average Life Cycle (hours) |

|---|---|---|

| Granite | 25–35 | 8–12 |

| Marble | 30–40 | 10–15 |

| Engineered Quartz | 35–45 | 12–18 |

Unlike traditional blades prone to vibration-induced chatter, the 400H model incorporates a patented segmented rim structure with micro-notches that reduce frictional heat buildup by up to 22%. This not only enhances operator comfort but also prevents thermal cracking—an issue often seen in low-quality blades after just 3–4 hours of continuous use. Additionally, the integrated cooling fins allow airflow even at moderate RPMs (1,200–1,800), keeping the blade surface below 120°C during extended runs—a key safety metric for professional users.

A case study from a major Italian tile fabrication plant using 400H blades for 24/7 production reported a 40% reduction in downtime due to blade replacement over six months. One foreman noted: “We used to change blades every 5 hours—we now get 8–10 hours of uninterrupted work. That’s not just efficiency—it’s profitability.” Another client in Dubai confirmed that the blade’s ability to maintain sharpness through multiple materials reduced rework rates by nearly 30%, directly improving job site quality control.

These outcomes aren’t accidental—they’re the result of rigorous engineering focused on what truly matters: durability over cost-cutting shortcuts. In an industry where time equals money, choosing tools that last isn’t just smart—it’s essential.

If you're serious about maximizing productivity without sacrificing quality, it’s time to stop settling for average. The 400H brazed diamond saw blade delivers exactly what top-tier contractors and manufacturers demand: consistency, reliability, and unmatched value per cut.