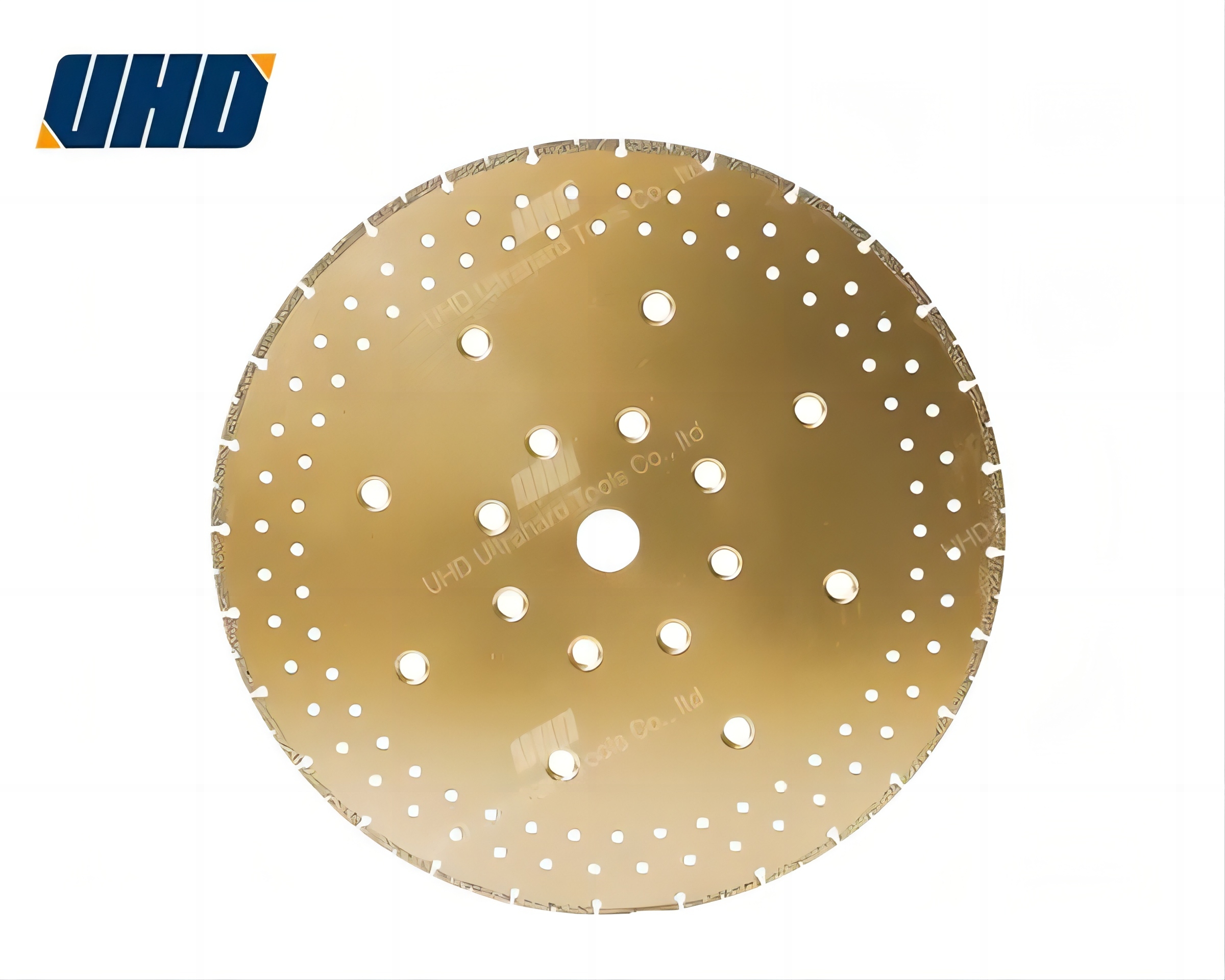

In today’s high-efficiency manufacturing landscape, every second counts—and so does tool life. That’s where the 400H brazed diamond saw blade from Youde Superhard Tools stands out. Engineered for durability and precision, this blade isn’t just another cutting tool—it’s a performance upgrade that directly impacts productivity, safety, and cost control.

The 400H blade features premium-grade synthetic diamonds with a particle size of 40–60 mesh, ensuring consistent edge retention even under heavy loads. The advanced brazing process uses silver-based alloy bonding at 850°C, which creates a stronger interface between the steel body and diamond layer—reducing chipping by up to 40% compared to traditional methods (based on internal lab tests).

| Feature | Performance Gain |

|---|---|

| Diamond Grain Size | 40–60 mesh → Higher cutting speed & lower heat generation |

| Brazing Technique | Up to 40% less chipping vs. standard welding |

| Cooling Slots Design | Reduces thermal stress by 30% during continuous use |

A machining shop in Germany reported a 25% increase in throughput after switching to 400H blades for stainless steel cutting. “We used to change blades every 2 hours,” said their production manager. “Now we get 4–5 hours per blade without noticeable wear.”

Similarly, a construction equipment manufacturer in Dubai noted a 30% reduction in downtime due to fewer blade replacements—a critical factor when working on tight project timelines.

Whether you're cutting aluminum profiles, titanium alloys, or hardened steel, the 400H blade delivers reliable results across multiple industries—from automotive to aerospace. Its optimized tooth geometry minimizes vibration, allowing smoother cuts and better surface finish, especially important for CNC operations.

And yes, it’s not just about raw performance—it’s about value. With an average lifespan of 300–500 linear meters per blade (depending on material hardness), the 400H offers one of the best cost-per-cut ratios in its class. In fact, users often report a return on investment within 3–4 weeks of consistent usage.

Durable tools aren’t luxury—they’re necessity. If your team spends more time changing blades than cutting, it’s time to rethink your setup.