In the industrial cutting field, professionals often face a series of challenges. Low cutting efficiency can significantly slow down the production process. For example, in a large - scale construction project, a low - efficiency saw blade may cause a delay of 1 - 2 days per week in the cutting of concrete components, which can lead to extended project timelines and increased costs. Poor wear resistance means that saw blades need to be replaced frequently. On average, a non - wear - resistant saw blade may need to be replaced every 10 - 15 cutting operations, adding to the material cost. Moreover, operation safety is also a major concern, as improper saw blades can cause accidents during the cutting process.

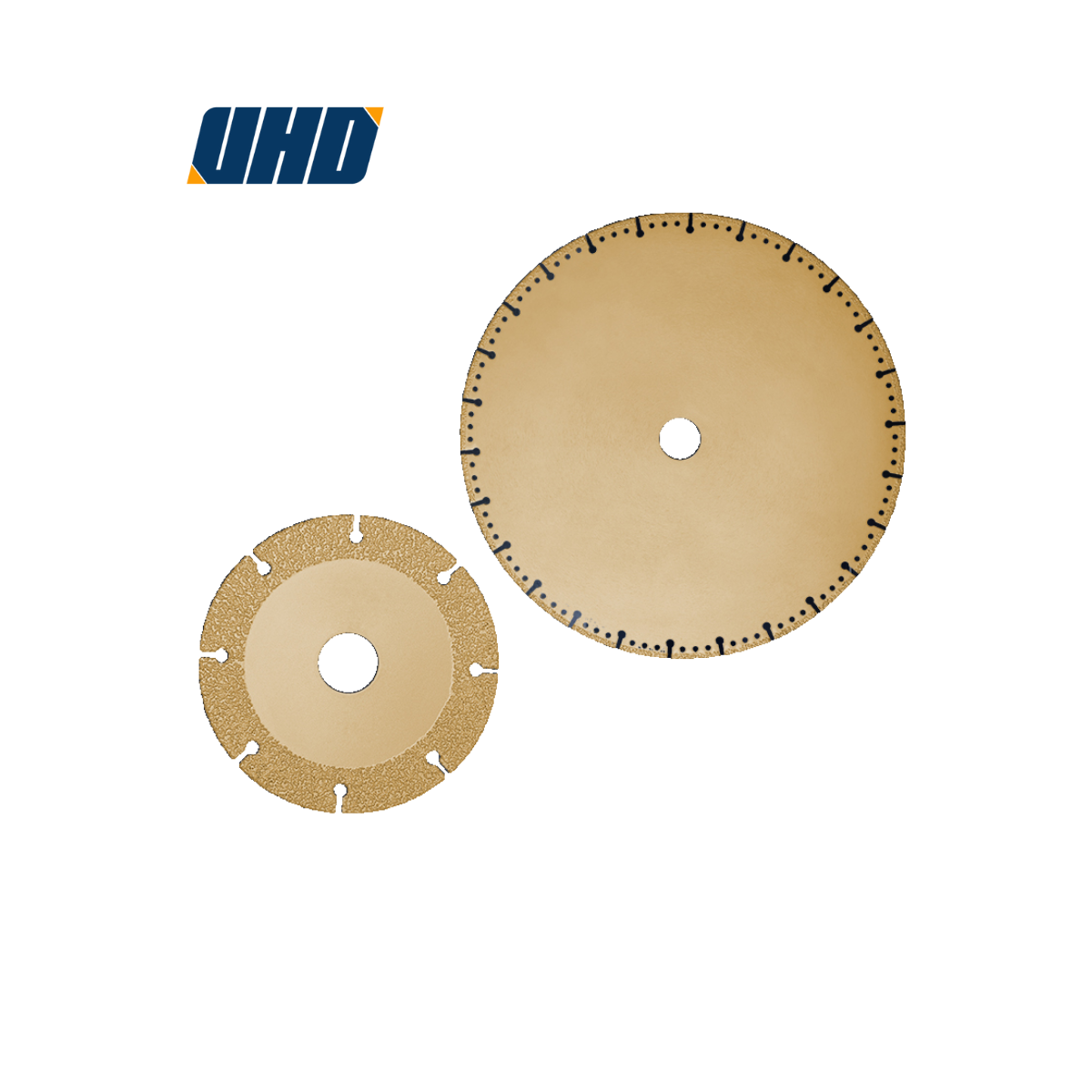

The 400H brazed diamond saw blade from Youde Superhard utilizes a high - strength brazing process. This process ensures a firm connection between the diamond segments and the blade body. In comparison to traditional saw blades, the brazed connection of the 400H saw blade can withstand 30% more stress during the cutting process. This means it can operate stably even under high - load conditions, reducing the risk of segment detachment.

It uses high - quality diamond materials. The diamonds have a high hardness and sharpness, which are crucial for efficient cutting. The diamond grade used in the 400H saw blade is among the top 10% in the market, ensuring excellent cutting performance on various hard materials. The innovative design of the saw blade, such as its unique tooth shape and segment arrangement, further enhances its cutting efficiency and stability.

In the construction industry, the 400H saw blade is widely used for cutting concrete. It can cut through concrete with a compressive strength of up to 50 MPa at a speed that is 20% faster than ordinary saw blades. For example, in a building foundation construction project, the 400H saw blade can complete the cutting of concrete columns in a shorter time, improving the overall construction efficiency.

When it comes to stone processing, the saw blade shows its excellent performance in cutting granite, marble, and other stones. It can maintain a smooth cutting surface with minimal chipping. In a marble processing factory, the use of the 400H saw blade has reduced the scrap rate of marble slabs from 5% to 2%, saving a significant amount of raw materials.

For tile cutting, the 400H saw blade provides high - precision cutting. It can cut tiles of various thicknesses and sizes with an accuracy of up to ±0.1 mm, meeting the high - standard requirements of interior decoration projects.

The 400H saw blade offers customized services. Different industries may have different requirements for saw blades, such as blade diameter, segment shape, and diamond concentration. Youde Superhard can customize saw blades according to the specific needs of customers. In terms of cost - effectiveness, although the initial investment in the 400H saw blade may be slightly higher, its long service life and high cutting efficiency can significantly reduce the overall cost in the long run. For example, in a large - scale stone processing plant, the use of the 400H saw blade can save up to 30% of the cutting cost per year.

Many customers have given positive feedback on the 400H saw blade. A construction company said that since using the 400H saw blade, their construction progress has been accelerated, and the number of saw blade replacements has been reduced by half. A stone processing factory mentioned that the smooth cutting surface provided by the saw blade has improved the quality of their products, leading to more orders. These real - world cases demonstrate the excellent performance of the 400H saw blade.

Discover the power of the 400H brazed diamond saw blade and boost your productivity now!