In the realm of industrial cutting, traditional cutting tools have long been plagued by a significant issue: excessive dust generation. According to industry statistics, in some metal - cutting workshops, traditional tools can produce up to 15 grams of dust per hour of operation. This dust not only poses a severe threat to the health of workers but also has a negative impact on production efficiency.

Exposure to high levels of dust can lead to various respiratory diseases, such as pneumoconiosis, which reduces the workforce's physical fitness and increases absenteeism. Moreover, the dust can contaminate the working environment, affecting the precision of other equipment and increasing the frequency of equipment maintenance, thus reducing overall production efficiency.

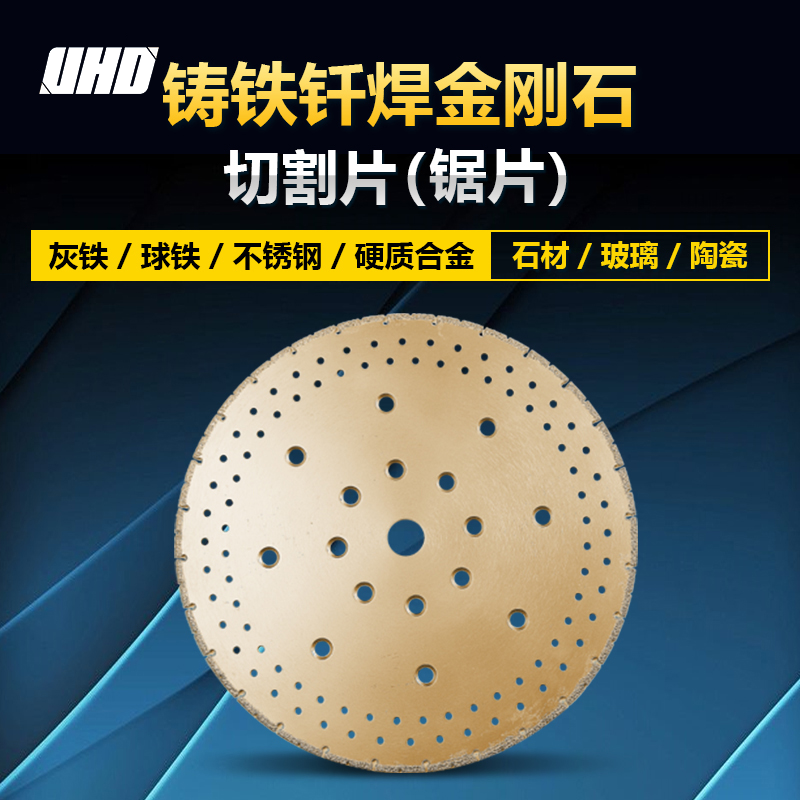

Brazed diamond saw blades offer a revolutionary solution to the dust problem with their core technological innovations. Firstly, the high - precision tooth profile design plays a crucial role. This design reduces cutting vibration, which in turn decreases the amount of dust generated during the cutting process. Tests have shown that compared with traditional saw blades, the vibration of brazed diamond saw blades can be reduced by up to 30%, resulting in a significant reduction in dust.

The ultra - thick high - manganese steel substrate also contributes to dust control. It enhances the stability of the saw blade during cutting, preventing excessive wobbling that could generate more dust. Additionally, the use of advanced diamond particles enables efficient and low - dust cutting. These high - quality particles can cut through materials more smoothly, reducing the friction and heat that cause dust to be released.

The optimized cooling system is another key innovation. By reducing heat - related dust generation, it ensures a cleaner cutting environment. And the precise size control of the saw blade minimizes ineffective friction, further reducing dust production.

In real - world applications, brazed diamond saw blades have demonstrated remarkable effects on improving workshop air quality, employee health, and compliance. For example, in a large - scale metal processing factory, after replacing traditional saw blades with brazed diamond saw blades, the dust concentration in the workshop decreased by 40% within a month. This not only improved the working environment for employees but also helped the factory meet environmental protection regulations more easily.

An expert in industrial safety commented, "Brazed diamond saw blades are a game - changer in the field of industrial cutting. They not only protect the health of workers but also contribute to a more sustainable production environment."

When compared with resin saw blades, brazed diamond saw blades have distinct advantages. Resin saw blades typically have a shorter service life, often needing to be replaced every 100 - 150 hours of use. In contrast, brazed diamond saw blades can last up to 500 hours or more. This longer service life means a lower replacement frequency, which not only saves on operating costs but also is more environmentally friendly.

A comparison table below shows the differences:

| Saw Blade Type | Service Life (hours) | Replacement Frequency | Operating Cost |

|---|---|---|---|

| Resin Saw Blades | 100 - 150 | High | Relatively High |

| Brazed Diamond Saw Blades | 500+ | Low | Relatively Low |

Brazed diamond saw blades also show stable performance when processing complex workpieces. Whether it is cutting irregular shapes or hard - to - cut materials, these saw blades can maintain a high level of cutting quality and dust control. This comprehensive performance advantage makes them an ideal choice for modern industrial cutting operations.

Don't miss out on the opportunity to upgrade your cutting tools. 立即了解如何为您的工厂带来更清洁、更安全的切割体验 (Discover now how to bring a cleaner and safer cutting experience to your factory)