In the industrial cutting sector, the choice of cutting tools significantly impacts operational efficiency and cost. Traditional saw blades often bring about a series of challenges, such as frequent replacements, low efficiency, and excessive dust generation. These issues not only lead to increased downtime but also create an unfavorable working environment, ultimately affecting overall productivity.

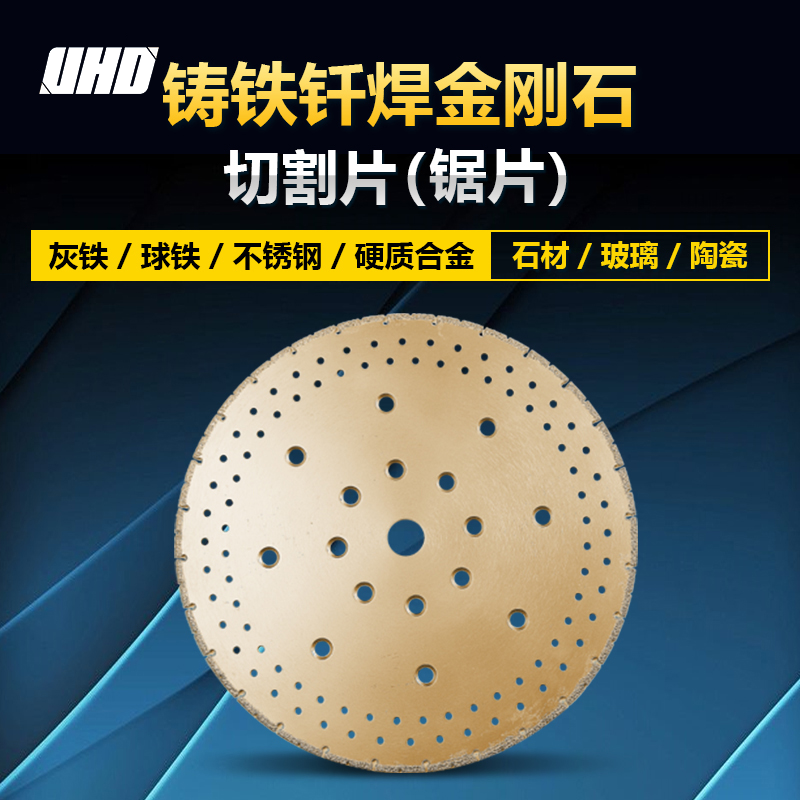

Brazed diamond saw blades represent a significant technological leap in the field of industrial cutting. They are designed with advanced diamond particles and a high - manganese steel substrate. The use of high - quality diamond particles ensures superior hardness and wear resistance, while the unique design of the high - manganese steel substrate provides excellent stability and strength.

When compared with traditional resin saw blades, brazed diamond saw blades offer several distinct advantages:

| Aspect | Brazed Diamond Saw Blades | Resin Saw Blades |

|---|---|---|

| Service Life | [Data box] Measured to have a service life extended by up to 300%. This means a significant reduction in replacement frequency. | Require frequent replacement due to rapid wear. |

| Sharpness | Maintain sharpness throughout the cutting process, ensuring consistent cutting performance. | Lose sharpness quickly, resulting in reduced cutting efficiency. |

| Safety | Generate less dust and vibration, providing a safer working environment. | Produce more dust and may cause greater vibration, posing potential safety risks. |

Brazed diamond saw blades are highly versatile and suitable for precise cutting of complex workpieces. They can handle materials such as gray cast iron, stainless steel, and ceramics with ease. For example, in the processing of gray cast iron, the high - performance of these saw blades ensures smooth and accurate cuts, which is difficult to achieve with traditional saw blades.

Let's take a look at some real - world data. In a manufacturing plant that processes stainless steel parts, the use of brazed diamond saw blades has reduced the saw blade replacement frequency from once every 10 hours to once every 40 hours. This represents a 75% reduction in replacement frequency, which directly translates into significant cost savings and increased productivity.

By choosing brazed diamond saw blades, manufacturing users can enjoy a range of benefits. Firstly, the reduced replacement frequency means less downtime for saw blade changes, allowing for continuous production. Secondly, the lower dust generation helps to optimize the working environment, protecting the health of workers. Finally, the overall productivity is significantly enhanced, as the saw blades can maintain high - quality cutting performance for a longer period.

To sum up, brazed diamond saw blades are the ideal choice for industrial users aiming to enhance cutting efficiency and reduce operational costs. They offer a sustainable solution for cost - reduction and efficiency - improvement in your factory. Let every cut be more worry - free and efficient! Choose our brazed diamond saw blades now!