In the realm of industrial cutting, precision and efficiency are of utmost importance. Brazed diamond saw blades have emerged as a revolutionary solution, offering unparalleled performance in various cutting applications. This article delves into the innovative design of brazed diamond saw blades and their significant impact on industrial precision cutting.

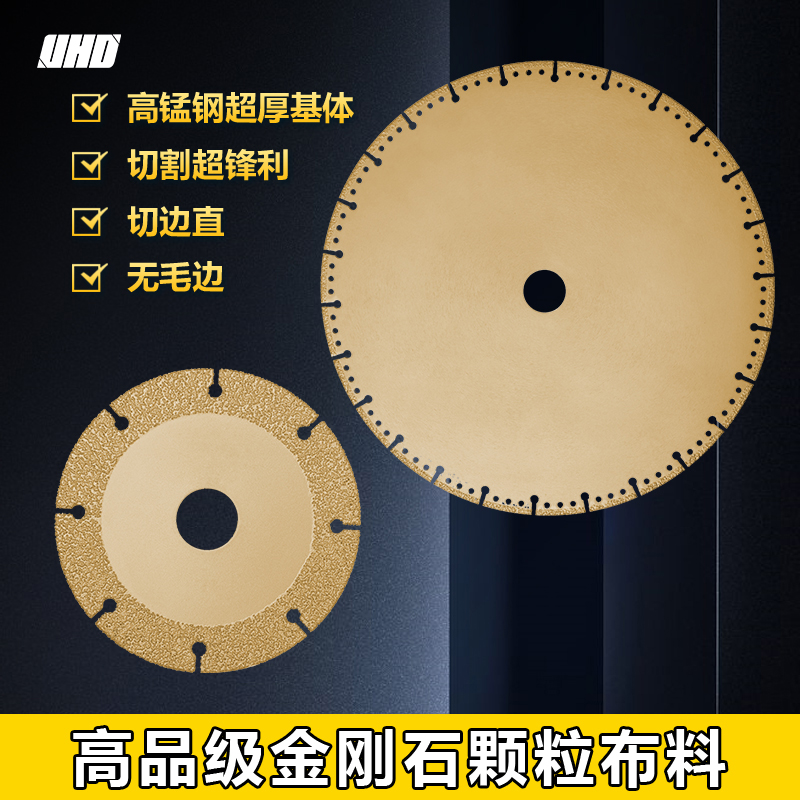

The brazing process plays a crucial role in enhancing the structural stability of diamond saw blades. By firmly bonding high - wear - resistant diamond particles to the saw blade, the brazing technology ensures a more secure connection compared to traditional methods. This results in a saw blade that can withstand high - intensity cutting operations without the risk of diamond detachment. As a result, the overall performance and reliability of the saw blade are significantly improved.

When comparing brazed diamond saw blades with traditional resin saw blades, the differences are striking. In terms of lifespan, brazed diamond saw blades outperform resin saw blades by a large margin. Tests have shown that brazed diamond saw blades can last more than 3 times longer than resin saw blades. This not only reduces the frequency of saw blade replacement but also lowers the overall cost of operation.

In addition, in terms of cutting accuracy, brazed diamond saw blades are much more precise. The stable structure and high - quality diamond particles enable them to achieve a smoother and more accurate cut. Moreover, the maintenance cost of brazed diamond saw blades is relatively low. With less frequent replacement and fewer adjustments, the cost of maintaining the saw blade is significantly reduced.

| Performance Indicator | Resin Saw Blades | Brazed Diamond Saw Blades |

|---|---|---|

| Lifespan | Short | More than 3 times longer |

| Cutting Accuracy | Relatively low | High |

| Maintenance Cost | High | Low |

Brazed diamond saw blades have excellent cutting performance on a variety of hard materials, including stainless steel, ceramics, and glass. Their high - strength diamond particles and stable structure enable them to cut through these materials efficiently and accurately. For example, when cutting stainless steel, the saw blade can maintain a high cutting speed and a smooth cutting surface, reducing the need for secondary processing.

The design of the high - manganese steel matrix in brazed diamond saw blades significantly enhances safety and impact resistance. High - manganese steel has excellent toughness and strength, which can effectively absorb the impact energy generated during cutting operations. This reduces the risk of saw blade breakage and improves the safety of operators. In addition, the high - manganese steel matrix can also improve the overall stability of the saw blade, ensuring a more consistent cutting performance.

One of the significant advantages of brazed diamond saw blades is their advanced dust control technology. Compared with traditional saw blades, brazed diamond saw blades can reduce dust generation by up to 50%. This not only improves the working environment for operators but also meets environmental protection standards. With less dust in the air, the risk of respiratory diseases for operators is reduced, and the overall air quality in the workshop is improved.

.png)

In conclusion, brazed diamond saw blades are a reliable, efficient, and environmentally - friendly cutting solution. Their innovative design and excellent performance make them an ideal choice for industrial precision cutting. If you are looking for a cutting tool that can bring high - efficiency, low - cost operation, and a greener working environment, click here to learn more about the specific application scenarios of our brazed diamond saw blades.