Dust pollution has long been a pressing issue within the construction and building materials sector, severely impacting worker health and onsite efficiency. Conventional cutting tools often generate excessive dust, aggravating respiratory hazards and hindering clear visibility on site. Are you facing similar challenges in your operations? Understanding how innovative cutting solutions mitigate these risks is key to safer and more productive workflows.

Fine particulate matter released during cutting processes, especially when working with stone, glass, and concrete, is a major source of occupational health complaints. Studies reveal that dust levels on typical construction sites can exceed five times the recommended exposure limits set by OSHA, leading to heightened risks of silicosis, chronic bronchitis, and other respiratory illnesses.

Traditional abrasive and diamond-coated saw blades often fall short due to imprecise cutting geometry and substrate limitations, causing heat buildup and brittle fracture that generate more airborne dust. This not only compromises worker safety but also increases cleanup time and accelerates equipment wear—incurring hidden operational expenses.

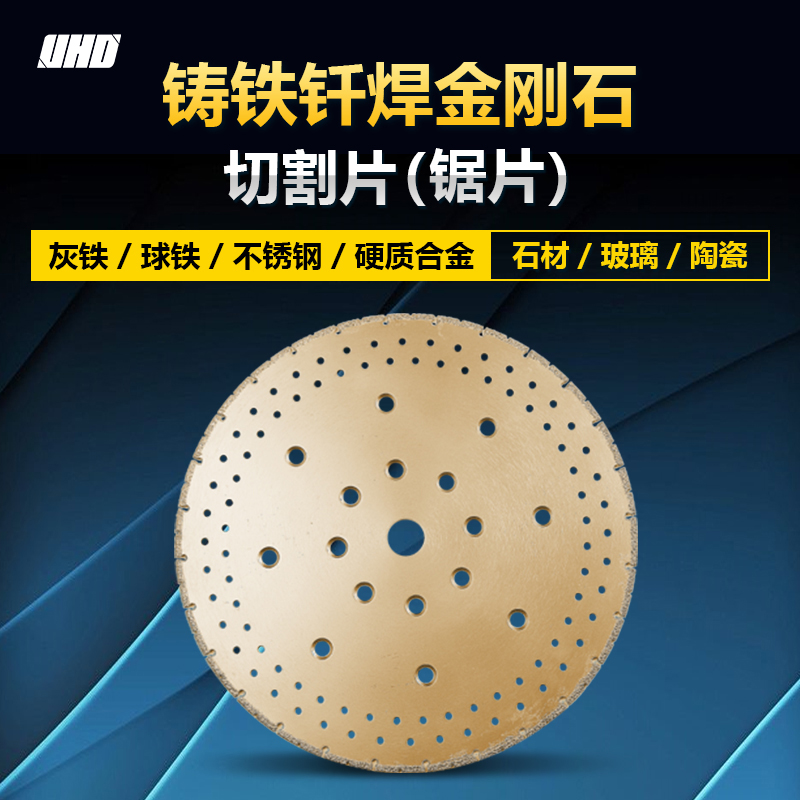

Brazed diamond saw blades are engineered with a high-manganese steel core combined with precisely profiled teeth, optimized for chip evacuation and minimal surface abrasion. The key innovation lies in the brazing process that securely bonds synthetic diamonds onto the blade’s edge, ensuring consistent grit exposure and sharpness throughout the blade's lifespan.

This advanced design reduces friction and localized heating, directly diminishing the generation of fine dust particles during cutting. Data collected from usage in various stone fabrication shops demonstrated a 45% reduction in airborne dust concentration compared to standard blades.

Within a high-output stone processing factory, brazed diamond blades demonstrated significant improvements. Measurements showed a notable drop from average dust particles of 120 μg/m³ to 66 μg/m³ during cutting sessions — a nearly 45% decrease. Workers reported clearer air quality and improved comfort, enabling longer work intervals without fatigue.

Similar effects were observed in a large-scale glass curtain wall assembly site, where precise cuts with brazed blades produced fewer hazardous silica dust emissions. This contributed to better compliance with local environmental safety regulations and reduced reliance on costly air-filtration equipment.

| Benefit | Impact |

|---|---|

| Dust Emission Reduction | Up to 45% lower particulate release |

| Blade Durability | Usage life improved 3 times over conventional blades |

| Cost Efficiency | Tool replacement costs cut by approximately 40% |

| Work Environment | Enhanced safety and comfort, promoting productivity |

These improvements converge to not only protect worker health but also reduce overall operational expenditures—helping you meet increasingly stringent green construction mandates with economic prudence.

Governments and regulatory bodies worldwide are amplifying their focus on environmental protection in construction. Compliance with guidelines such as EPA’s National Emission Standards for Hazardous Air Pollutants (NESHAP) and Europe’s Construction Products Regulation (CPR) requires adopting cleaner techniques and tools.

By investing in environmentally responsible cutting tools like brazed diamond saw blades, businesses position themselves competitively—showcasing commitment to sustainability while enhancing project outcomes.

Does your site struggle with dust pollution during cutting tasks? Take action now by exploring precision brazed diamond saw blades that reduce dust, lower costs, and improve work conditions. Discover the Solution for Safer, Cleaner Cutting >>