In the stone processing industry, the lifespan of saw blades is a crucial factor that directly impacts your production efficiency and cost. For instance, dry cutting often leads to chipping of the saw blade teeth, and uneven wear can cause you to replace the saw blade frequently. According to industry statistics, improper saw blade maintenance can increase your tool - replacement costs by up to 30%. That's why proper saw blade maintenance is the key to solving these industry pain points.

The installation of the saw blade is the first step in ensuring its long - term stability and performance. Balancing and calibration are essential. If the saw blade is not properly balanced, it can cause vibrations during operation, which not only affects the cutting quality but also significantly shortens the lifespan of the saw blade. The tightening torque is also crucial. Insufficient torque may cause the saw blade to loosen during operation, while excessive torque can damage the saw blade or the equipment. A proper tightening torque, usually within the range of 80 - 120 Nm for a 400 - millimeter saw blade, can ensure the saw blade's stability and safety.

When using the saw blade, controlling the feed rate is of great importance. A too - high feed rate can cause excessive pressure on the saw blade, leading to rapid wear and even breakage. For different types of stone, the recommended feed rate varies. For example, when cutting granite, the feed rate should be controlled at about 10 - 15 m/min. Avoiding dry cutting is another key point. Dry cutting generates a large amount of heat, which can damage the diamond layer of the saw blade. Using coolant can effectively reduce the temperature and extend the saw blade's lifespan. Additionally, you should select the appropriate saw blade according to the type of stone. Soft stones require a different saw blade design than hard stones.

Daily cleaning and proper storage are important for maintaining the saw blade's long - term performance. After use, you should clean the saw blade to remove stone chips and coolant residues. Rust prevention treatment is also necessary. You can apply a thin layer of anti - rust oil on the saw blade surface. When storing the saw blade, it should be placed in a dry and shock - proof environment to prevent it from being bumped or deformed, which can affect its cutting performance.

Common problems such as chipping and uneven wear often occur during the use of saw blades. Chipping may be caused by factors such as improper cutting parameters or low - quality saw blade materials. Uneven wear is usually due to incorrect installation or unbalanced cutting forces. The following table shows the common problems, causes, and solutions:

| Problem | Cause | Solution |

|---|---|---|

| Chipping | Improper cutting parameters, low - quality materials | Adjust cutting parameters, replace with high - quality saw blade |

| Uneven wear | Incorrect installation, unbalanced cutting forces | Re - install the saw blade, adjust cutting equipment |

The high - precision tooth profile design of the saw blade has many technical advantages. Structurally, the unique tooth shape can effectively reduce the cutting resistance, which in turn reduces the generation of dust. Functionally, it can improve the sharpness of the saw blade, making the cutting process smoother. According to experimental data, a saw blade with a high - precision tooth profile can reduce dust generation by about 20% and increase the cutting efficiency by about 15% compared to a conventional saw blade.

Let's take a construction company as an example. Before using the correct saw blade maintenance methods, they needed to replace the saw blade every 100 hours of operation. After implementing a comprehensive maintenance plan, including proper installation, correct usage, and regular cleaning, the saw blade's lifespan was extended to 200 hours. This shows that correct maintenance can double the saw blade's lifespan.

"Since we started following the scientific saw blade maintenance methods, our saw blade replacement cost has been reduced by 40%, and the cutting quality has also been significantly improved." - A construction company feedback

Q: Can I use the same saw blade for all types of stone?

A: No, different types of stone have different hardness and texture. You should choose a saw blade that is specifically designed for the type of stone you are cutting to ensure the best cutting performance and longest lifespan.

Q: How often should I clean the saw blade?

A: It is recommended to clean the saw blade after each use to prevent the accumulation of stone chips and coolant residues, which can affect the saw blade's performance.

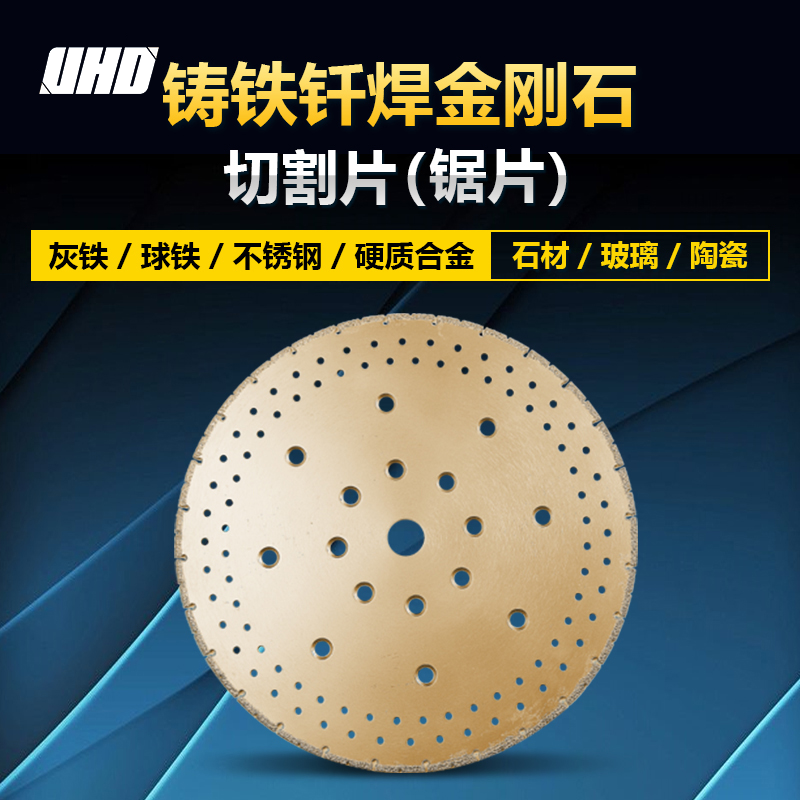

At UHD, we firmly believe in the philosophy of "Quality Builds Brands". Our UHD saw blades are crafted with the highest - quality materials and the most advanced manufacturing techniques. With a high - precision tooth profile design, they can effectively reduce dust generation, improve cutting efficiency, and extend the saw blade's lifespan. If you are looking for high - quality saw blades that can help you maximize your equipment performance and reduce costs, we invite you to view the details or get technical support.